Gas Valves for Boilers: Types, Characteristics, Methods of Work

What are gas valves? These are special mechanical devices that are designed to control the pressure and flow of gases, fluids, as well as slurries within the entire gas heating system. Such valves are also commonly referred to as regulators that are used in a pretty wide number of different applications. FYI, for all media types that are conveyed through pipes, there should be gas valves for boilers in order to control their flow.

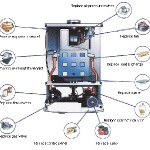

All gas valves for boilers differ in design, operation, size and function, not speaking of their capacity, outlet and inlet size, as well as type: step opening, standing pilot or slow opening. Selecting a valve, which can provide a satisfactory performance, the least amount of maintenance and valve life is of high importance.

What Does a Valve Do?

There is no need to mention that a gas boiler is the most important part of the central heating system. It is a big unit with a continuous supply of natural gas that is streaming into the appliance from a pipe and then goes out to a gas mine that is in the street.

When a person wants to heat his place, he simply switches on the gas boiler using and electric switch. What is happening then? A gas valve opens and natural gas enters a sealed combustion chamber in it through a vast number of small jets. Then an electric ignition system sets them alight. The jets play onto the pipe with cold water, thus heating it to a definite temperature (140°F).

The primer task of the valve is to control natural gas going into the burner chamber of a gas boiler. The valve itself is controlled by an aquastat and thermostat. Any valve of such type is created to regulate the gas flow into the burner, handle and control the flow of media (natural gas or/and liquefied petroleum). Being created for such special purposes, gas valves are made either of plastic or metal and usually vary in pressure rating, sizes, flow and number of ports.

Valves and Controls

It is highly important for controls and gas valves for boilers to match the fuel type of the heating system. Natural gas conversion kits are always available and the valve should be converted to meet the requirements of the system. When the type of the system is verified, its capacity should be determined as well. Whether a closed/open gas valve is selected normally, usually depends on the frequency and intensity of its usage.

Today there are three gas control valves for boiler. They include ODS, thermopile and single thermocouple systems. If we speak of the latter option, in this case one end of the thermocouple is heated, thus allowing natural gas to flow to the heater’s pilot. The majority of gas valves of the thermocouple system feature a so-called by-pass button, which enables pilot’s lightening as soon as the thermocouple is cold.

Then it allows natural gas to flow regardless of a rather slow heating of the thermocouple. This by-pass button can be released in 30 seconds. Then the flow of the gas should continue. Now you know how important gas vales for boilers are.

- popular

- new