Rules of Hot Water Boiler Maintenance. Answering Why, When and How Questions

Hundreds of hot water boiler accidents are reported day after day. Though most models are of the highest quality, with time they need repair or should be replaced, especially, if boilers aren’t maintained in a proper way. Do you know basic hot water boiler maintenance rules?

Daily/Monthly/Yearly Inspection

Daily maintenance is a quick and easy procedure to repeat. It includes a check of a burner operation: fuel pressure, steam or atomizing pressure and visual appearance.

When the fire is low or shutdown, clean the observation ports. Test the unit level alarms as well as low water cutoff. Repeating the same things daily, you’ll contribute to the lifespan of the boiler you use.

Monthly inspection includes the check of the refractory’s condition for any cracking or damages. When needed, patch and repair the refractory. Don’t forget to wash the coating frequently, using air-dry type mortar diluted with water for this very purpose. It will help out in sealing various small cracks and prolonging the lifespan of refractory. If there are large cracks, clean them out and fill with mortar.

Yearly inspection is the most serious procedure that should be repeated regardless of the fuel source – gas or oil. It should be a thorough yearly inspection done just before firing up the boiler for the winter season.

In case a hot water boiler system provides hot tap water all the year round, it is important to follow a certain schedule for the inspection as well as a recommended maintenance plan either found in a user manual or the one suggested by a service contractor.

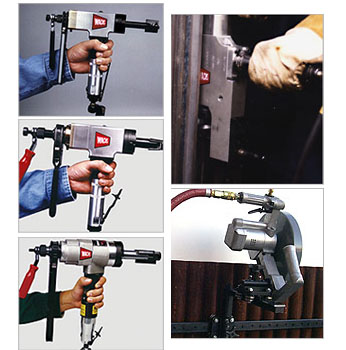

Such inspections are to be done by a heating contractor, a person, who specializes in various boiler systems and has both knowledge and experience to make you sure that your boiler is working in a proper way. No matter what boiler type you have, during the inspection a professional checks all main components: burners, casings, injectors, heat exchanges, probes and sensors.

The inside parts must be cleaned, checked and adjusted. In cases of gas boiler systems, the maintenance and servicing must include gas connections and valves, flue terminals and inner components to make sure whether they are properly vented.

Regular Running

The core of hot water boiler maintenance is running the heating regularly, at least once every month (even during summer period). Clear the boiler pump of the grit, which gathers, when the unit is not used. It helps to keep the boiler running efficiently.

Temperature & Time

Before a hot water boiler achieves efficient operation, the furnace must be raised to operating temperature. The fuel burning rate should be maintained in order to produce the needed number of pounds of steam per one hour to run it of turbines and supply for heat needs.

Make sure you keep to all the recommended rules of hot water boiler maintenance. This will help to cut down expenses on repair and will ensure the safety of your home and family.

- popular

- new