How Does a Gas Boiler Pump Work? How to Install It?

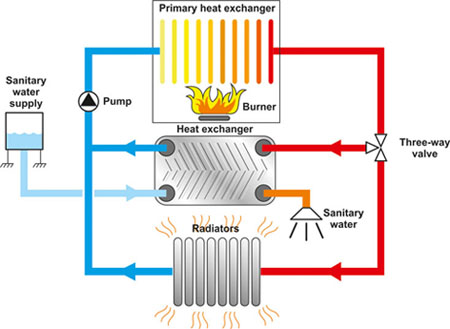

Gas boiler pumps take one of the important roles in the work of the entire gas heating appliance. Their primer task is to control the amount of water fed to the unit, as well as the manner in which this amount is fed. Let’s find out more.

A pump works controlling the liquid, which enters a heating unit as well as whether the liquid is fed in the proper way. Pumps become highly useful in cases of high pressure gas boilers, including water tube units that are commonly used in many industrial applications, as well as those, which work generating the superheated steam.

Generally speaking, most boiler models work only with water, which means that pumps shouldn’t be equipped in order to cope with more volatile or heavier fuilds. Their main characteristic feature is to be able to accelerate the used liquid and control the water flow at set rates.

Installing Gas Boiler Pumps

As it has already been mentioned, pumps send heated liquid throughout the heating system and then back to its heat source. This means that they play a great role in circulation, and are important items for you to know how to replace them or install.

Today many manufacturers have made great efforts, trying to make the installation and replacement process easier and efficient. However, far not everyone is able to cope with it. If you believe you can, consider our tips.

To begin with turn off the pump controller and the electricity to the boiler, the valve for water supply and the valve from the fuel supply.

It is also highly important to drain the boiler at the boiler drain using a garden hose, in case there are no isolation valves that could be used for the pump. Then you should better write down the water pressure that is in the gas boiler.

So, what to start the installation with? Use a screwdriver in order to remove the electric cover plate that is on the cartridge of the pump. Make sure you disconnect the wiring. Then start loosening the bolts that are on the flanges of the pump. While doing this, hold the pump in its place, using a pair of offset pliers. Then remove it. Mount the new pump with gaskets and install the four bolts, making sure you hold the pump to its flanges. Connect all the wires and then simply replace the cover plate.

For some people the gas boiler pump installation seems to be a pretty easy process, however, it is not. If you are not sure that you’ll manage with the task, you should better ask for a help of a professional. This will save much time and prevent possible problems and additional expenses in case of installation failure.

How Does a Pump Work?

The very first thing you should always keep in mind is the fact that thee are different types of boilers, which are used in many types of industrial and residential applications. This is why the number of pumping configurations and mechanisms is great as well.

The majority of modern pumps are centrifugal and multistate pumps. Besides, many gas heating units also require an adjustable and pretty specific rate of flow or their flow should be controlled by the special flow control system. This all allows industrial facility’s operators regulate the heat and pressure amount, which is usually created by a gas boiler.

- popular

- new